By submitting your data, you are providing us with some level of personal information. This information is not stored on our website database. However, in order to respond to your enquiry, your data is emailed to our website’s email address where it is saved. Additionally, we may use your contact details to send you marketing material in the future. You may unsubscribe from any emails you receive following our first reply. We do not pass your data on to any third parties.

Our Software Features

We Do Dairy

- Process Optimisation

- Dairy Focused

- Real Time Data Acquisition

- Smart Data Mining

- Instrument Interface

- Configurable

- Process Transparency

- Fully Traceable in minutes

- Risk Reduction

- Integrated

- Multi Site

- Regulatory & Accredited Standards Audit compliance

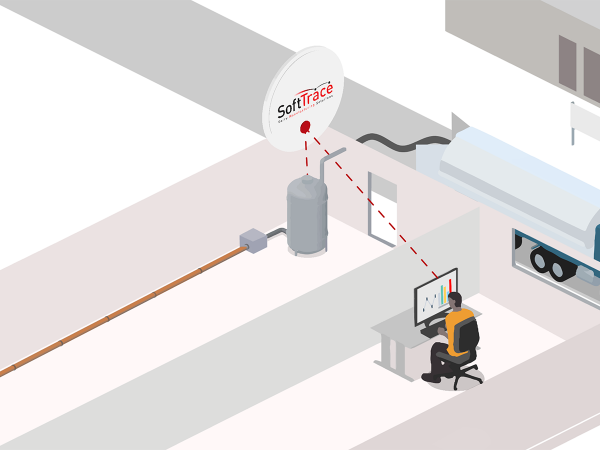

Bulk Liquids Intake

Intake management of bulk liquids in dairy is both specific and complex. Capturing critical relevant data from multiple sources, such as variable composition, volume measurement, silo and process allocation, load traceability and quality analysis can be challenging.

The SoftTrace Intake Management system is a configurable and unique software for milk dairy management that brings with it the exact precision required to measure, calculate and manage bulk liquids of variable composition.

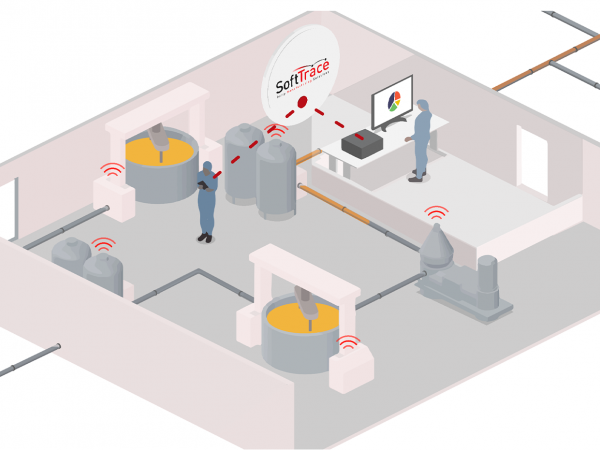

Process Manufacturing

SoftTrace has collaborated with globally recognised dairy manufacturers to create production process management dairy software that delivers industry-specific functionality.

SoftTrace In Process functionality was developed to fully Integrate with the manufacturing process to monitor & control detailed information on the make up of any batch of bulk finished product to packed finished product units.

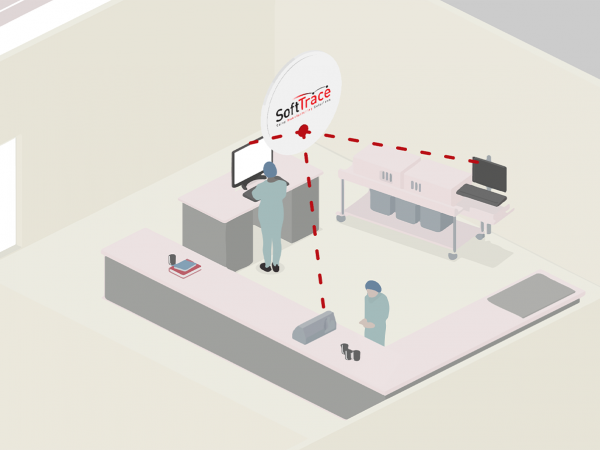

Quality Analysis & Compliance

The SoftTrace Quality Analysis & Compliance Management software system is a fully scalable, flexible laboratory and quality process data milk management system.

Today’s Dairy industry is committed to achieving best practice standards of quality and compliance in response to growing customer specification, accredited standards, and regulatory requirements.

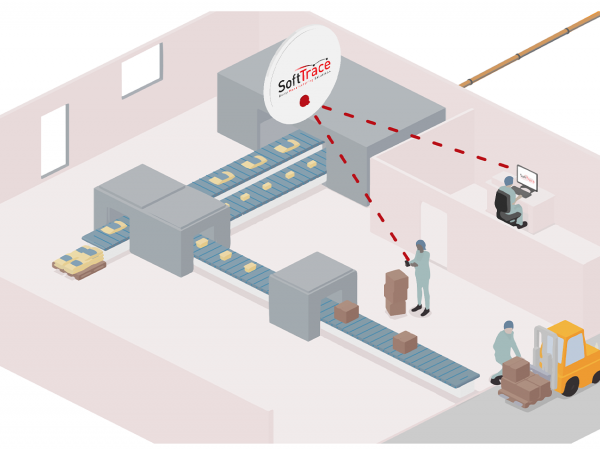

Finished Goods, Inventory & Dispatch

SoftTrace Inventory Management optimises your stock movements by accessing critical data in real-time, offering full visibility of stock and stock movements in minutes.

Access to a full range of reports on stock grades, locations, shelf life, transfer, and movement, including purchase order, sales order, truck manifest, dispatch summaries and invoicing

What our clients say...

"Using SoftTrace MilkData we have achieved significant improvements in the general running of the laboratory. We have increased control over sample test scheduling and achieved a rapid turnaround of..."

"Today the emphasis is on verification and speed. Being able to quickly demonstrate full traceability as well as rapid response capabilities is the key to gaining a competitive advantage...."

"We chose SoftTrace because of the systems focus on the dairy industry. As the implementation progressed we became increasingly impressed with the systems flexibility and customizability. We have been..."

"We selected SoftTrace because of its focus on traceability and quality control, its modularity, its configurability, and the SoftTrace team’s experience in providing software to the food industry."

"SoftTrace works for IFF because it has been designed specifically to enforce GMP compliance and it integrates easily wit our ERP, laboratory, process automation and barcoding systems. "

"It has been a pleasure to work with the SoftTrace team, they are receptive to our needs and concerns. SoftTrace have a level of food industry expertise that has..."